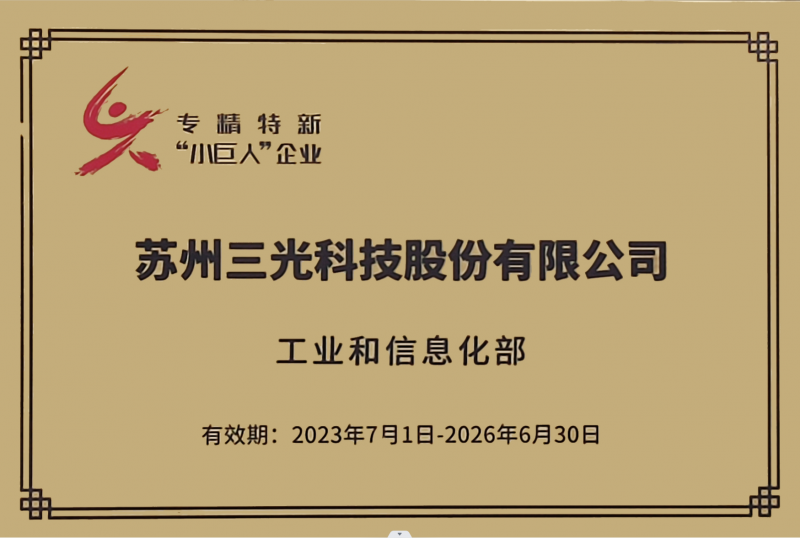

国家第五批专精特新“小巨人”企业名单完成公示。

苏州三光科技股份有限公司通过相关审核,顺利荣获2023年第五批国家级专精特新“小巨人”企业称号!

专精特新是指具有“专业化、精细化、特色化、新颖化”的“四化”特征。

专精特新“小巨人”企业是指专注于细分市场、创新能力强、市场占有率高、掌握关键核心技术、质量效益优的排头兵企业!

本次入选国家级专精特新“小巨人”企业,进一步提升了三光科技知名度,增强三光品牌核心竞争力和行业影响力,三光科技始终坚持自己的经营理念,不断完善,加大研发,引进技术,推进制造,把一代一代承载着高行业标准和先进技术的电加工产品推向市场并推动了中国电加工行业蓬勃发展!

● 苏州三光科技股份有限公司具有60年历史,是专业生产、销售电加工机床的高新技术企业,国内首家上市的电加工企业。

● 三光科技先后参加了国家科技重大专项“863”计划项目的研发工作。

● 1993年至今三光科技一直被认定为江苏省高新技术企业,产品被认定为江苏省名牌产 品,

"3G"商标被认定为江苏省著名商标,获得中国机械工业科学技术二等奖。

● 2017年中走丝HB400机床荣获德国 iF 设计奖,同年该型号机床又荣获 红点 设计大奖。