2018 DMP智博会于11月27日-30日在东莞厚街广东现代国际展览中心如期举行,三光科技(展位号:3A-231)期待您的光临!

本次展会锦鲤:三光科技匠心之作——EA500数控电火花成形机,

除此之外,三光还带来了其他几款机型,让大家一饱眼福:

一、奖项满贯的HB数控伺服系统中走丝机床新成员——HB600!

二、多年良好口碑中走丝——HA400U数控中走丝机床!

三、LA500A精密数控慢走丝机床!

聚三光研发团队多年智慧结晶,传承三光优良品质——EA500数控电火花成形机上市!

延续三光一体机设计风格,X/Y轴独立结构。

延续三光一体机设计风格,X/Y轴独立结构。

全套日本THK导轨/丝杠,进口直线光栅尺,交流伺服电机实现全闭环。

全套日本THK导轨/丝杠,进口直线光栅尺,交流伺服电机实现全闭环。

自动升降油槽,三面开口。

自动升降油槽,三面开口。

加工液恒温控制。

加工液恒温控制。

丰富的摇动功能。

丰富的摇动功能。

简单的人机交换界面。

简单的人机交换界面。

.......

这款三光锦鲤,只有你想不到,没有我们做不到!

HB系列数控伺服系统中走丝新成员-——HB600

※四轴交流伺服结合四轴进口滚珠丝杠及直线导轨,带来高精度保证。

※X轴与Y轴独立布局,UV轴桁架式结构保证高精度。

※大厚壁铸件及加强筋的配置抑制床身变形。

※框型挡水结构、切削液不再外泄。升降式挡水板方便工件安装、节省空间。

※LED照明灯及工作状态指示灯,时刻掌握设备运行。

※两种走丝方式满足不同加工需求,更换导轮变得简单。

※导轨丝杠集中润滑,保持车间环境干净整洁。

※高速无电解电源,抑制电解腐蚀的发生,防止形成“软化层”,提高表面质量。

※人机交互系统,工艺参数库

※操作台位置随意调整,操控得心应手。

……

HA400U数控中走丝机床

U系列中走丝机床,豪厘之间,绽放新能量!

微小的能量调整带来工艺的改变。

凭着对品质的毫不妥协,三光科技将中走丝技术推到了新的高度!

※最佳表面粗糙度突破Ra 0.6μm

※加工速度提升到 300mm²/min

※无电解电源改善加工品质

※X、Y轴进口交流伺服控制使切割速度快、精度高。

高效、高精度、高节能的慢走丝—LA500A

※三维实体造型、高刚性结构、大臂厚铸件加强筋优化配置。

※高精度进口导轨、丝杠、光栅尺提高定位精度消除方向间隙,确保高精度。

※热熔断剪丝系统,实现快速自动穿丝,提高穿丝成功率。

※电动升降门、液位自动控制、使浸水加工更轻松稳定。

※快捷菜单设计,15寸大屏幕触摸屏操作简单易学。

※高性能手控盒近台操作,更加得心应手。

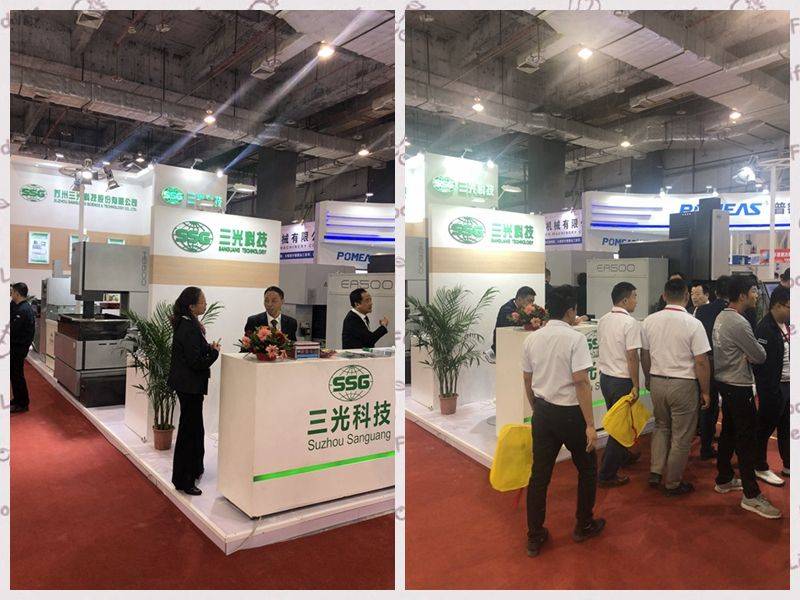

现场火爆照片: